Products

We deals with mechanical products for various types of industries in Malaysia.

Our high quality products are bearings, belts, and power transmission products such as roller chains, couplings, sprocket gears, pulley and lubrication

Bearing is a mechanical element that rotates and its main function is to reduce friction in a moving machinery devices or system. By smooth rotation and linear-free motion, It ensures the stress acting in the system to be distributed evenly, thus reduced risk of catastrophic system failure. There are various type of bearings which designed for different type of applications. From consumer products such as motorbike and washine machine to crusher in quarry plant, all of these are using bearings in its application.

Most common type of bearings are ball bearing and roller bearing. Ball type bearing is suitable for high rotational speed and lesser load while roller bearing is specifically design to take up heavy load but with slower speed.

- Deep Groove Ball Bearing

- Spherical Roller Bearing

- Cylindrical Roller Bearing

- Thrust Bearing

- Housing Unit Bearing

- Needle roller bearing

- Linear motion Bearing

Why Choose Yik Bee

Our bearing services including diagnosing failure-condition monitoring, bearing mounting and dismounting and shaft alignments. We also provide rental of bearing induction heater.

Main Brands

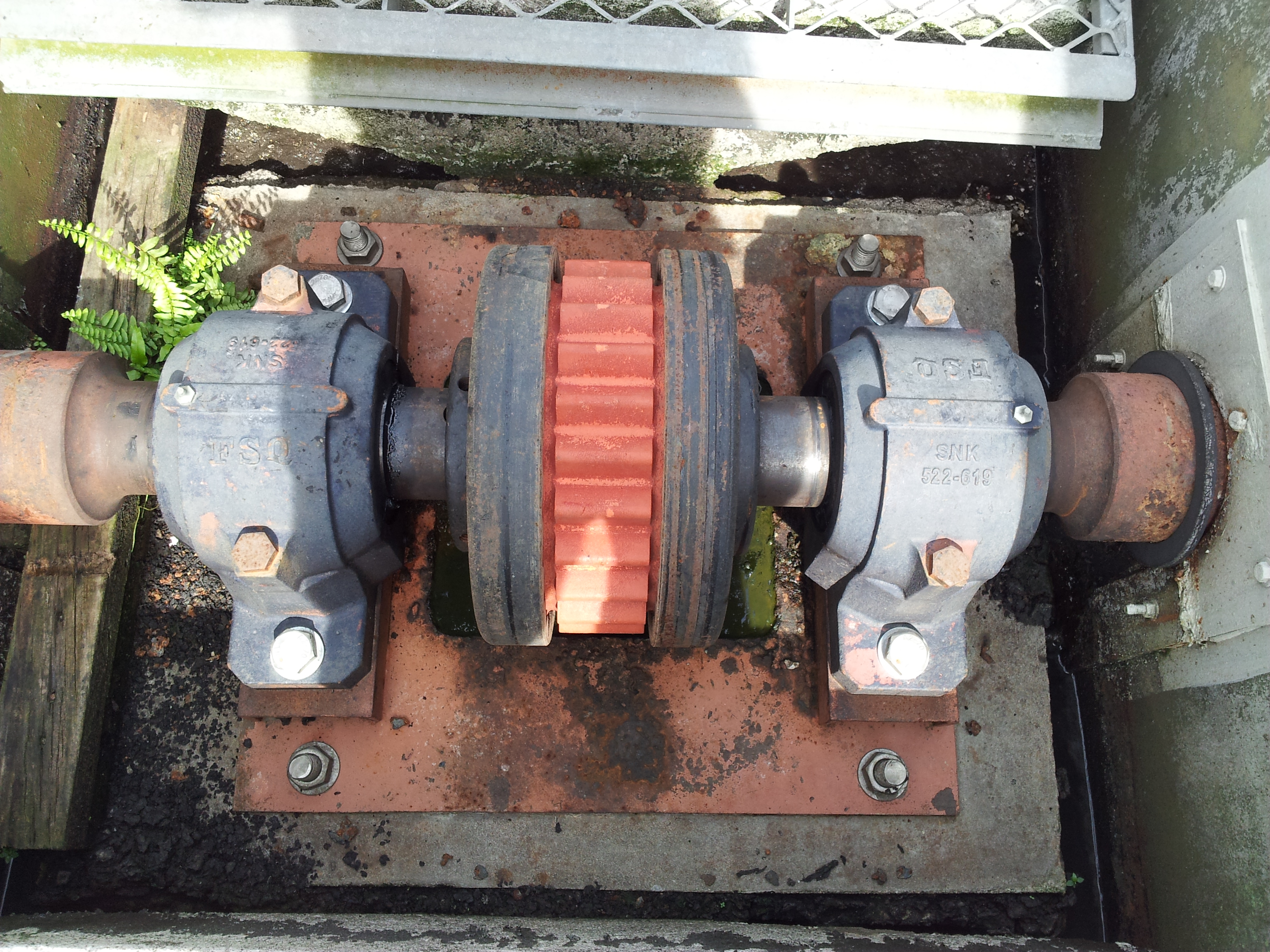

The most common way to transfer power from one shaft to another is by using belt drive. The belt is attached to the driver pulley (power source) in parallel to the driven pulley. With the wide range of application in industry, there are several type of commonly used belts mainly are Vee Belt, Timing Belt and Conveyor Belt.

Belt such as A,B,C series or SPA/SPB/SPC/SPZ series are called as vee belt and friction driven. The cross-section which is V-shape running in the pulley groove by sidewall, thus create frictional force. The advantage of vee belt is high power transfer, and less cost.

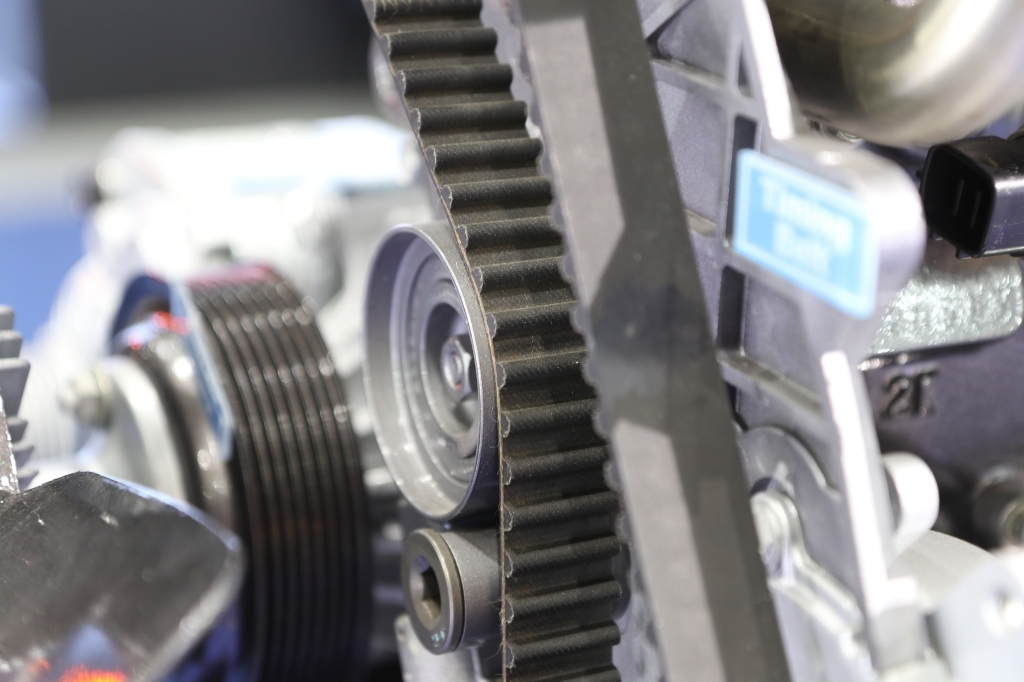

Meanwhile, a timing belt (tooth design) is running by positive drive system which is driven by timing pulley. The advantage of timing belt is no-slippage and higher efficiency compare to vee belt drive but with slightly higher cost. Most commonly seen application in our everyday life is at our car engine.

- Conventional Vee Belt- A,B,C,M

- Wedge Belt - SPA,SPB,SPC,SPZ

- Variable Speed Belt- RPF

- Special Vee Belt - QuadPower, Predator…

- Timing Belt Series

- Polychain Belt

- Link Belt

- Tension Tester and Sonic Meter

- Alignment tools- Ez Align

Why Choose Yik Bee

Alternatively, Yik Bee is moving forward to help our customer in energy saving with polychain belt and save to downtime cost with Link Belt.

Main Brands

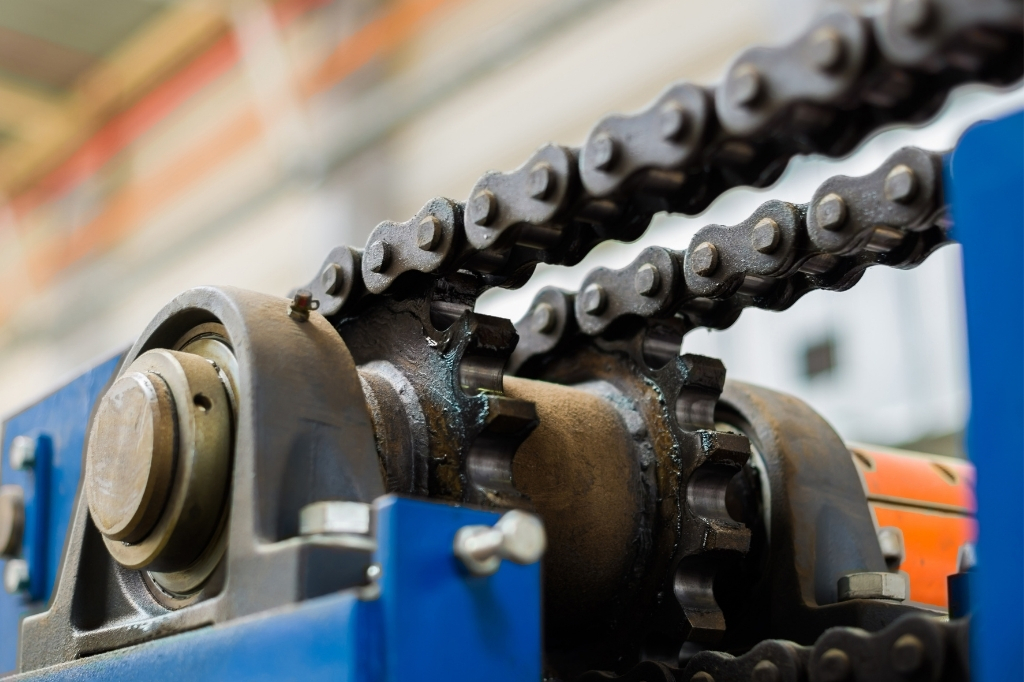

Chain is a mechanical component to transfer power. The design of chain which is using positive drive system, made it widely used in various applications as very less friction occurred, thus less energy is lost during operation. Most common type of chain is roller chain or power transmission chain, using sprocket gear to link the roller chain by its teeth. The biggest advantage of roller chain is that it can transfer heavy load and no risk of slippage.

With its straightforward design, metal material to provide resistance to shock load, and cost efficient, roller chain can be found on many applications either in heavy industry such as palm oil mills to our everyday use transport such as motorcycle and bicycle.

- Roller Chain

- Stainless Steel Chain

- Conveyor Chain

Why Choose Yik Bee

The most important maintenance of roller chain is lubrication, and Yik Bee is working closely with our customers to ensure roller chain is properly lubricated and on time through our campaign and lubrication training.

Main Brands

Coupling is the mechanical element widely used in many applications. Its main purpose is to join two pieces of rotating equipment while permitting some degree of misalignment or end movement. By connecting two drive elements together, the torque or rotational power is transmitted from one end to another.

Coupling can be categorized into two types which are mechanical flexi and material flexi coupling. These two type of couplings accept misalignment but differ in lubrication. Material flexi coupling do not require lubrication while mechanical flexi needs to be lubricated. Example of material flexi couplings are Jaw coupling and Tyre Coupling while gear coupling is the mechanical flexi coupling.

Coupling Type and Classification :

- Jaw Coupling and Sleeve Coupling

- Pin and Bush Coupling

- Tyre Coupling

- Gear Coupling

- Disc Coupling

- Grid Coupling

Why Choose Yik Bee

Main Brands

Lubricant is a substance used to reduce friction by two contact surfaces. The used of lubricant will prevent metal to metal contact, and ensure smooth motion of the machinery application. It is important to use the correct type of lubricant since it will contribute to machine efficiency, prolong its life, thus reduce downtime.

Study indicates that most bearing failure is due to improper lubrication process, either wrong selection of lubricant or amount to be applied. The selection of lubricant can be based on several important factors such as operational condition, temperature and speed. Choosing a wrong type of lubricant will not just work inefficiently, but will speed up the bearing failure.

- Grease

- Aerosol Grease Spray

- Oil

Why Choose Yik Bee

With our wide range of lubricants and tools, and strong technical support from the manufacturer, we ensure to always help your machinery to work efficiently and prolonging its lifespan.

Main Brands

Bearing Mounting and Dismounting Tools

Flexihook Spanner or Torque Wrench

Come in several sizes, from locknut KM 9 to KM 24. Send inquiry to us for further details.

Puller and Hydraulic Puller

Bearing Induction Heater

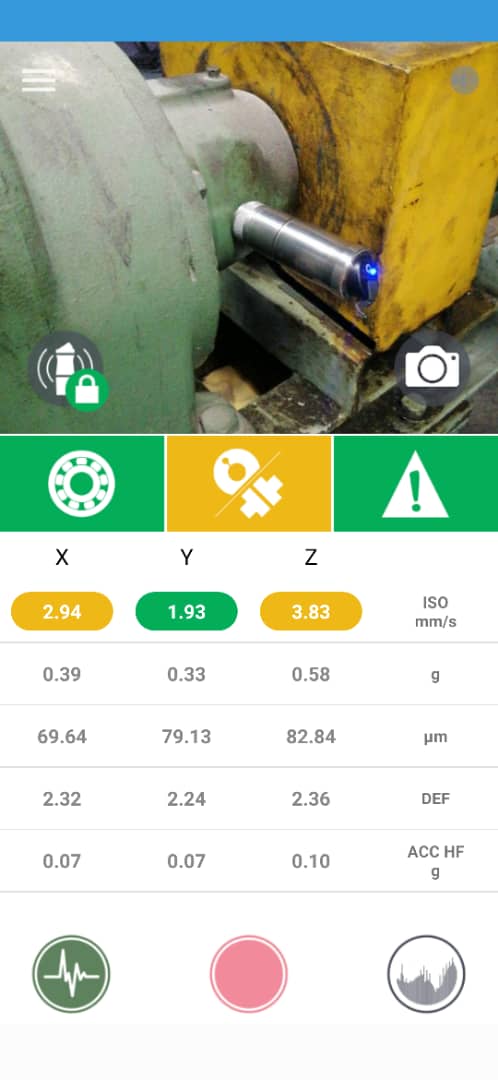

Condition Monitoring Device

FAG Detector 3 is used to capture and analyze the vibration of any rotating machinery such as bearing and gear. Through this device, any premature bearing failure can be detected earlier and zeroing the risk of catastrophic bearing failure which led to unplanned shutdown. High mobility, easy to use and detailed results are what make detector 3 is a must have device to help monitoring all your machinery.

FAG Smart Check is used to capture and analyze the vibration of rotating machinery. Online monitoring and multiple port-channel are what making Smartcheck the leader in condition monitoring device. With multiple port, you can maximise the efficiency by capturing multiple vibration tests from more than one machinery at the same time. And with its online feature, you can even set up for the test result to be notified at your mobile phone right away.

Belt Maintenance Tools

- Sheave Gauge : A tool used to check the pulley sheaves. Come in handy for any engineer, fitter to check the pulley condition and size. Came in complete sizes of vee belt pulley.

- Tension Tester Pen type: Came in single barrel and double barrel type, is a tool to check belt tension. Deflection force is measured at the tester and the results will be compared to Gates tension table. Conventional method, using hand-feeling which highly practiced by factory worker, should be replaced with this cost efficient and high accuracy tool.

- Digital Sonic Meter U-508: An advanced tension tester to accurately check the belt tension in the shortest time. The parameter needs to be keyed-in, then capture the vibration of the belt to get the tension results. Unlimited data can be saved to its memory. A must device for any plant using timing belt.

- EZ Align Laser Tools: To check belt and pulley alignment with reflection of laser to its mirror. Easiest method to check the alignment in fast and accurate ways. Just need to attach it’s magnet side to the pulley surface, then adjust the pulley until the laser is in parallel. Easy.

Smart Check

Gates Sheave Gauge

FAG Laser Trummy

Tension Pen

One Prod